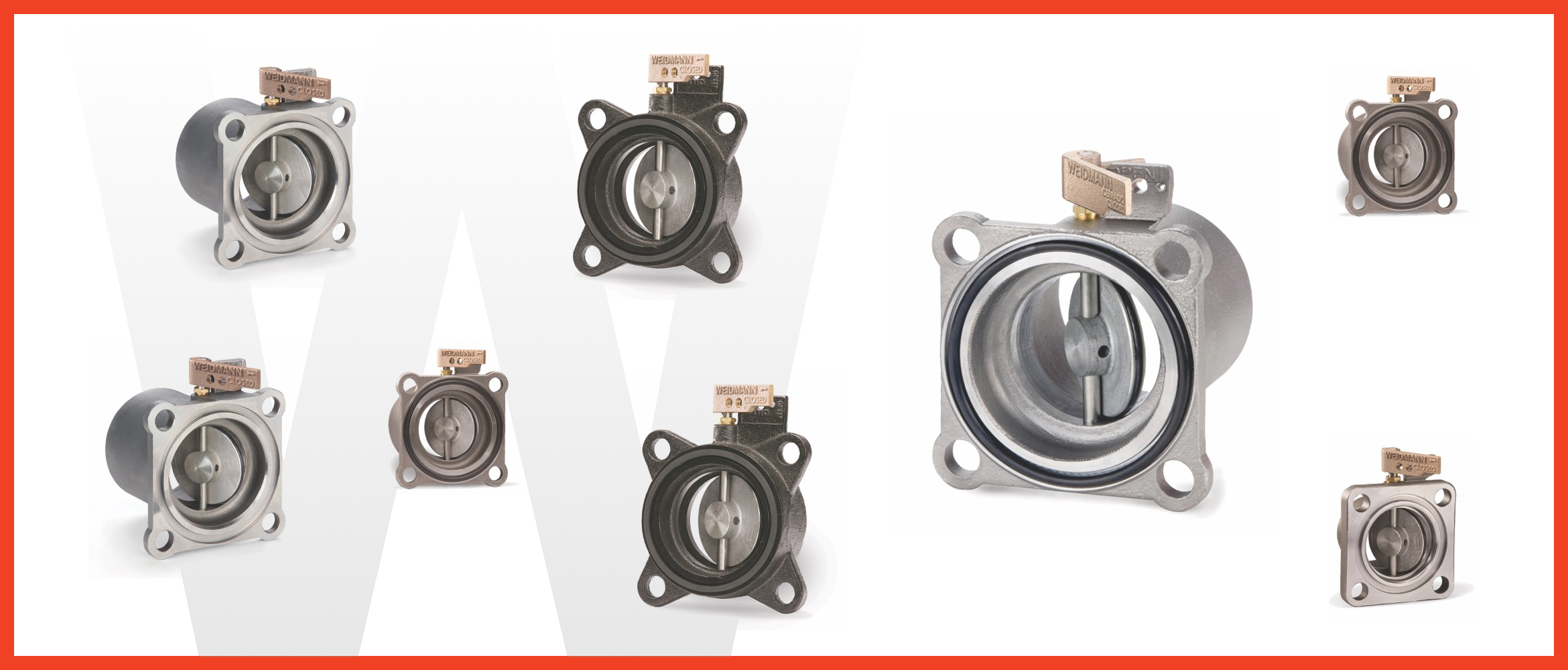

Radiator Valves for Power Transformers

Advanced sealing technology and 100% testing that ensure leak-free valve performance.

Radiator valves are essential components in oil-immersed power transformers. Welded or bolted to the transformer tank, they support the attached radiators or heat exchangers that increase a transformer’s loading capacity by decreasing the oil temperature. Radiator valves also allow transformers to be shipped without radiators and easy radiator removal for maintenance or replacement without draining the insulating oil.

While radiator valves represent a small portion of a transformer’s total cost, a leaking valve can result in significant expenses for both manufacturers and end users. To meet industry demands for durability and leak-free performance, all Weidmann radiator valves undergo 100% leak testing using a highly accurate hydrogen tracer gas method to ensure maximum reliability. In North America, Weidmann valves are offered in weld-on or bolt-on designs compatible with 3-inch and 4-inch diameter radiators.

Precision Manufacturing and Testing

Weidmann radiator valves for power transformers are machined in conjunction with UBW in the United States using state-of-the-art equipment. Valves are produced and 100% tested under an ISO certified Quality Management System. A computer-monitored mass flow testing process is used, with testing accuracy maintained, pass/fail, at a 0.1 CC/minute leak rate limit, which calibrates to zero observable leakage for transformer applications.

Benefits of Radiator Valves for Power Transformers

- By controlling the flow of transformer oil from the transformer tank to radiators or heat exchangers, radiator valves help to increase the loading capacity of the transformer.

- Radiator valves offer utilities the ability to remove radiators easily from transformers for the purposes of repair, maintenance, or replacement.

- Radiator valves allow for radiators to be installed on transformers at their final destination.

Product Summary

- Provides ease of assembly and installation.

- Offers optimum product support with rapid deployment of corrective actions or assistance when required.

- Manufactured with a high level of precision in an ISO certified facility.

- Tight tolerances, continuous measuring, and thorough testing throughout the manufacturing process guarantee uniformity of dimensions for reliable installation.

- Weidmann valves undergo 100% testing before being shipped to ensure a leak-free design.

- Weidmann offers in-house valve design services, custom testing, and engineering services.

- Valves, accessories, replacement parts, and local warehousing are available in the United States, Mexico, and Canada.